the making of the limited edition longitude

ENG300 SERIES

MOVEMENT ASSEMBLY

PLAY VIDEO

the eng376

The 22 jewelled ENG376 movement boasts an enviable technical specification. With a depth of 4.95mm and diameter of 25.6mm, the ENG376 features a 65-hour power reserve, a silicon escapement, a custom balance bridge designed to reflect the architecture of Bremont’s state-of-the-art headquarters at The Wing, the home of British watchmaking, and the automatic movement is powered by a full tungsten rotor.

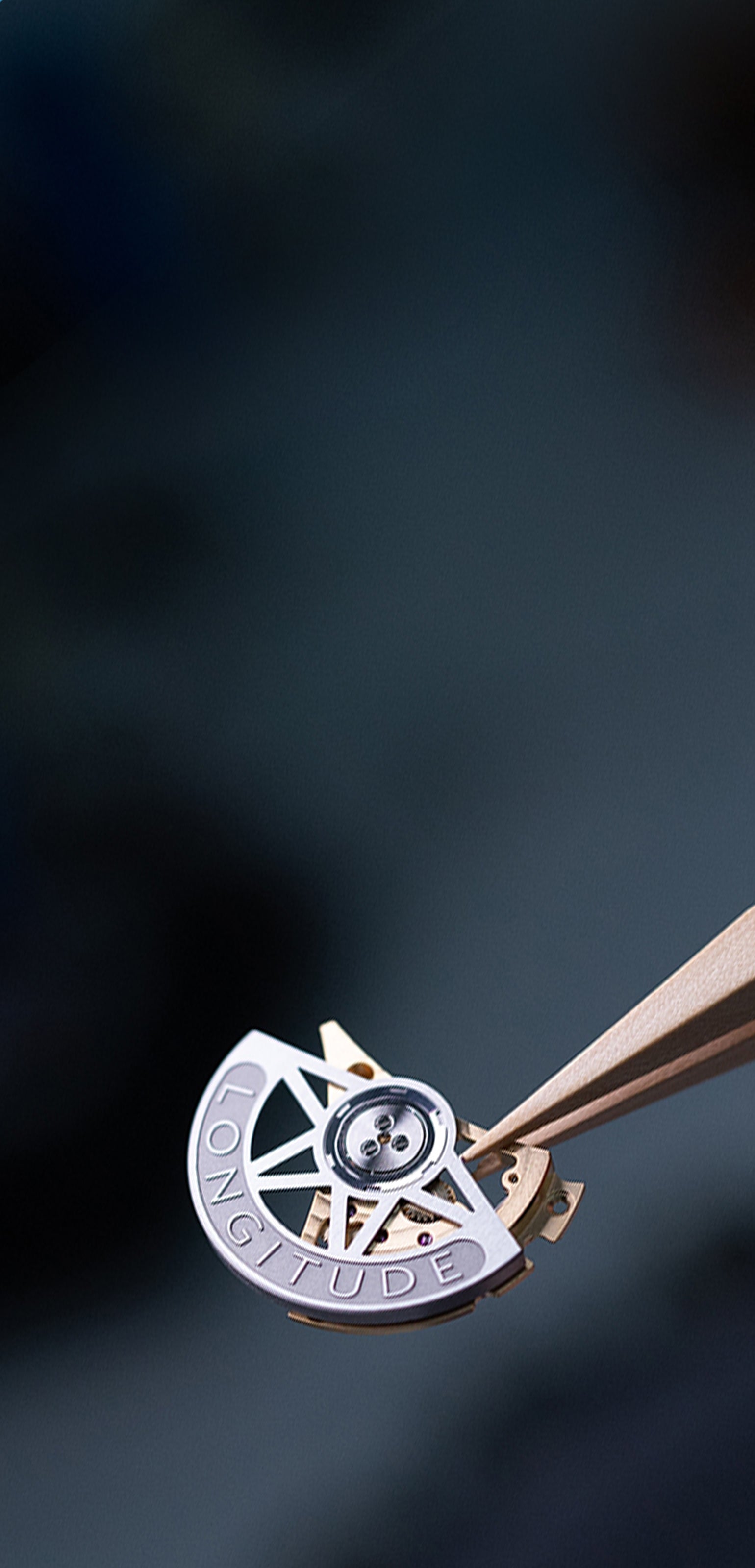

the beating heart

A significant component in this process is the free sprung balance wheel. This is the beating heart of the ENG376. 4 x Ø0.4mm screws are used to adjust the regulation, whilst the combination of the shock protection and a full balance bridge protect against vibration and shock loads.

jewel setting

Movements are carefully inspected prior to assembly of the Automatic Module. A stereo microscope gives a superior depth-of-field whilst a high definition camera projects the image to a screen to aid with training and data logging.

Precision instruments such as the automated AxNum stone pressing machine play an essential role in our expanding in-house capabilities. The machine allows Bremont to be able to meet the high quality requirements for the construction of watch movements.

the finishing touches

The Automatic Bridge is assembled with the one piece tungsten balance weight before completing the movement assembly. The 3 screws securing the bridge use a threadlocking compound to prevent them working loose as the oscillating weight spins.